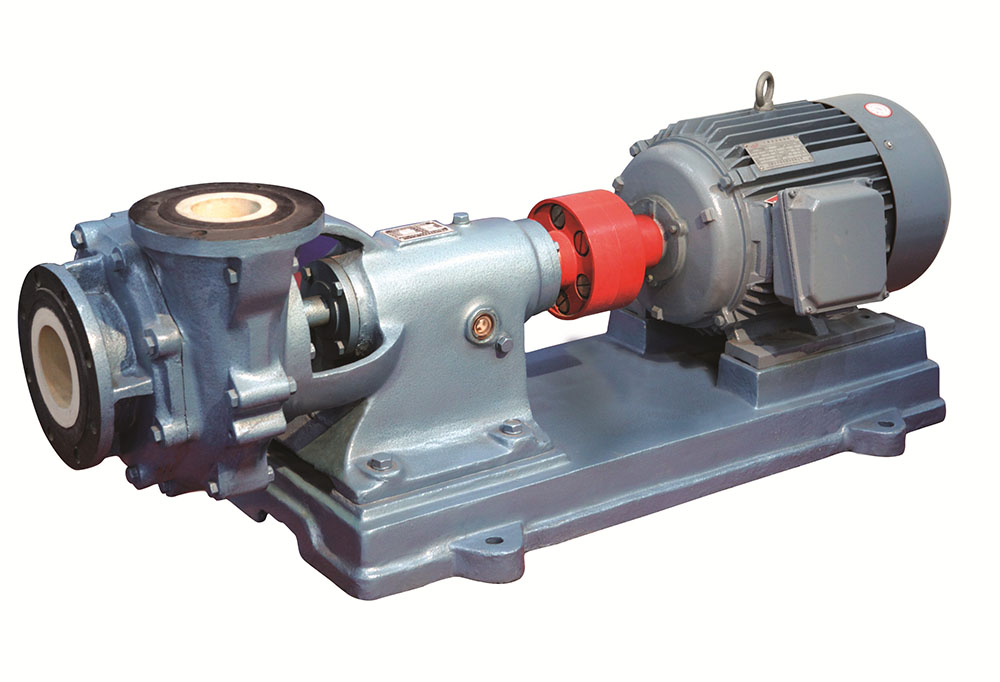

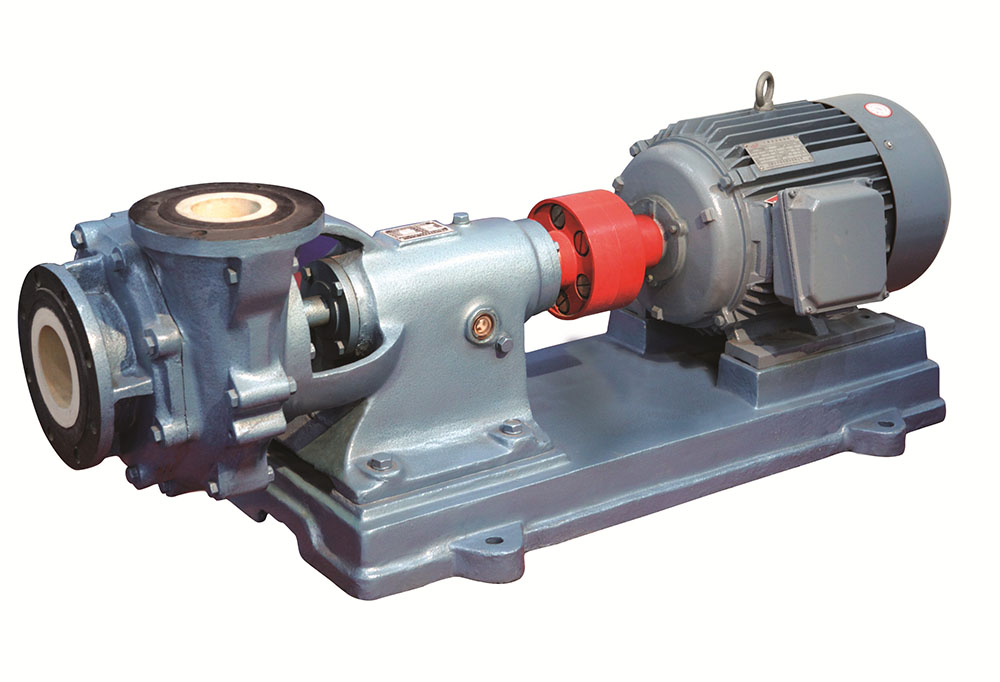

1, Product Introduction

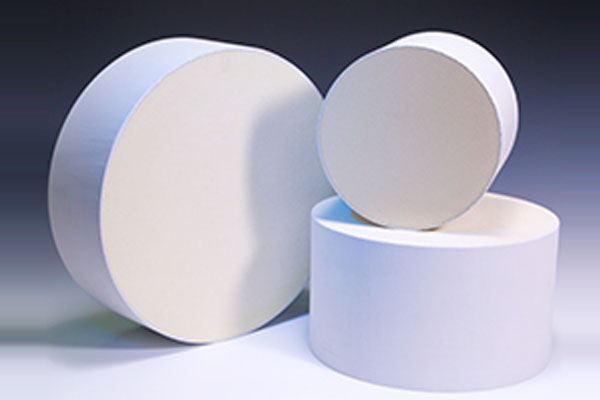

HTB-ZK series corrosion-resistant ceramic pump, which belongs to single-stage single-suction cantilever centrifugal pump. The pump body and pump cover are made of corrosion-resistant, wear-resistant, and acid-resistant ceramics, with cast iron armor outside. The impeller material is engineering ceramics or engineering plastics. The pump has good corrosion resistance, compact structure, tight shaft seal, no pollution to the medium, convenient installation and maintenance, and reliable use. The application range is very wide.

2, Performance Summary

Pump flow: 5~240m3/h: 10~60m, the shaft seal structure adopts a back blade pressure reduction combined with a fluororubber oil seal ring or a secondary impeller centrifugal seal. The pump has the characteristics of corrosion resistance, wear resistance, convenient maintenance, and reliable use, suitable for conveying various corrosive media containing suspended solid particles except hydrogen fluoride and hot concentrated alkali solution. The use temperature is lower than 100℃ (the use temperature of engineering plastic impellers depends on the material and medium), and the temperature difference is less than 50℃.

3, Application Range

It can be widely used in mining, metallurgy, chemical industry, petroleum, pesticide, dye, wastewater treatment and other processes to convey corrosive media containing solid particles.

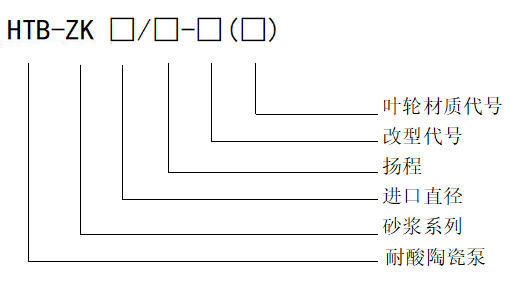

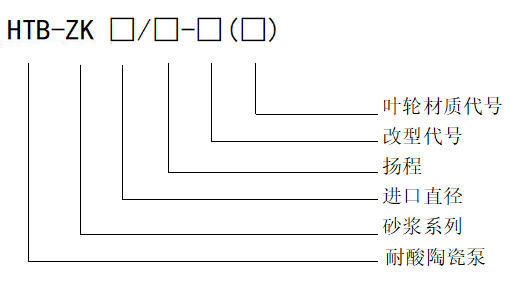

4, Model Description

Impeller Material Code

|

Material

|

Ceramics |

Ultra-high molecular weight polyethylene |

Modified rubber and plastic |

Fluoride alloy |

Polyvinylidene fluoride |

Polyether chloride |

Stainless steel |

Silicon carbide

|

| Corrosion resistance and wear resistance |

Heat resistant and wear-resistant |

Corrosion resistance |

| Code name |

Not marked |

S |

S1 |

S3 |

S2 |

S4 |

S5 |

S6 |

G |

C |

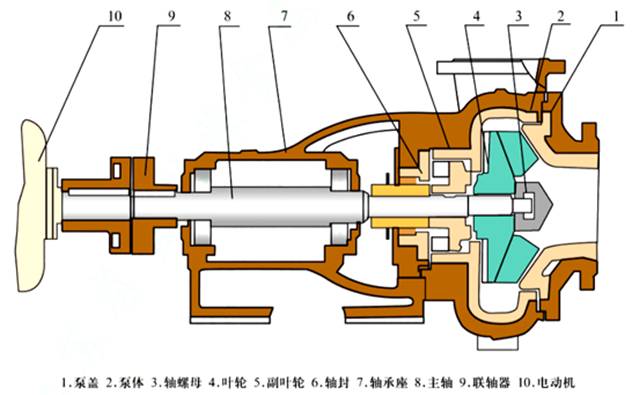

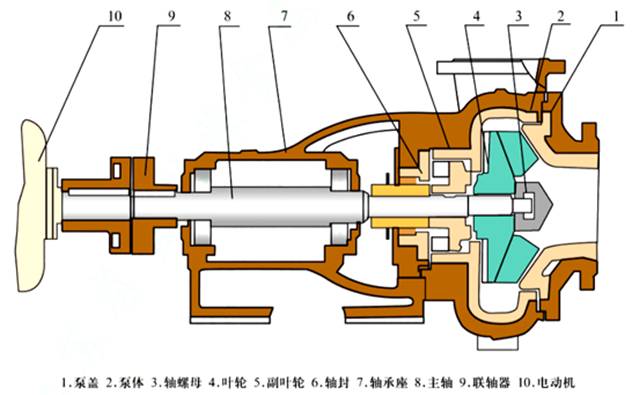

5, Structural type

6, Detailed parameters

|

Parameter \ Model

|

impeller specifications |

Rated speed 2900 rpm |

Rated speed 1450 rpm |

Vaporization

Margin

(m) |

Weight

(kg) |

| Flow rate Q (m3/h) |

Head H

(m) |

Motor power N medium specific gravity

(Kw) |

Efficiency η

% |

Flow rate Q

(m3/h) |

Range

H

(m) |

Motor power N medium specific gravity

(Kw) |

Efficiency η

% |

HTB-

ZK4.0/20 |

Standard |

5 |

24 |

2.2 |

33 |

|

|

1.5 |

|

4.0 |

60 |

| 10 |

20 |

37 |

5 |

5 |

| 15 |

16 |

35 |

|

|

| A |

5 |

12 |

1.5 |

26 |

|

|

|

|

| B |

5 |

15 |

1.5 |

26 |

|

|

|

|

| C |

8 |

10 |

1.5 |

27 |

|

|

|

|

HTB-

ZK5.0/30 |

Standard |

10 |

33 |

5.5 |

40 |

5 |

8.2 |

1.5 |

|

4.0 |

110 |

| 20 |

30 |

43 |

10 |

7.5 |

| 30 |

27 |

41 |

15 |

6.7 |

| A |

30 |

22 |

5.5 |

36 |

|

|

|

|

| B |

20 |

20 |

4.0 |

35 |

|

|

|

|

| 25 |

18 |

5.5 |

36 |

|

|

|

|

HTB-

ZK6.5/50 |

Standard |

25 |

51.5 |

15 |

36 |

12.5 |

12.8 |

3 |

|

5.0 |

220 |

| 30 |

50 |

41 |

15 |

12.5 |

| 40 |

45 |

39 |

20 |

11.2 |

| A |

15 |

50 |

11 |

35 |

|

|

|

|

| B |

20 |

45 |

11 |

35 |

|

|

|

|

| C |

25 |

40 |

11 |

35 |

|

|

|

|

HTB-

ZK8.0/30 |

Standard |

30 |

32.8 |

11 |

43 |

15 |

8.2 |

2.2 |

|

5.0 |

188 |

| 40 |

30 |

48 |

20 |

7.5 |

| 50 |

29 |

46 |

25 |

7.2 |

| A |

30 |

27 |

7.5 |

42 |

|

|

|

|

| 40 |

25 |

7.5 |

44 |

|

|

|

|

| 50 |

23 |

11 |

45 |

|

|

|

|

HTB-

ZK10.0/35 |

Standard |

50 |

37.5 |

18.5 |

50 |

25 |

9.4 |

3 |

|

5.0 |

220 |

| 60 |

35 |

52 |

30 |

8.8 |

| 70 |

31 |

49 |

35 |

7.8 |

| A |

50 |

32 |

15 |

50 |

|

|

|

|

| 60 |

29 |

|

|

|

|

HTB-

ZK15.0/25 |

Standard |

|

|

|

|

150 |

28 |

37 |

58 |

6.0 |

410 |

| |

|

220 |

25 |

65 |

| |

|

240 |

22 |

60 |

| A |

|

|

|

|

150 |

35 |

45 |

49 |

| |

|

|

|

200 |

32 |

52 |

| |

|

|

|

240 |

28 |

50 |

HTB-ZK15.0/40 |

Standard |

|

|

|

|

120 |

43 |

37 |

51 |

6.0 |

520 |

| |

|

150 |

40 |

45 |

58 |

| |

|

200 |

37 |

45 |

56 |

| A |

|

|

|

|

100 |

45 |

37 |

50 |

| B |

|

|

|

|

130 |

35 |

30 |

52 |

| C |

|

|

|

|

160 |

45 |

45 |

56 |

HTB-

ZK15.0/25-D |

Standard |

|

|

|

|

100 |

27 |

30 |

53 |

6.0 |

360 |

| |

|

|

|

120 |

25 |

57 |

| |

|

|

|

140 |

24 |

58 |

| A |

|

|

|

|

85 |

22 |

15 |

46 |

| |

|

|

|

100 |

20 |

50 |

| |

|

|

|

120 |

18 |

52 |

7, Pump external dimensions and installation dimensions

.png)

|

Model

|

Power

(kW)

|

With

Motor

|

Installation dimensions

|

|

|

|

|

D1

|

D2

|

d1

|

d2

|

B1

|

B2

|

n1-s1

|

n2-s2

|

n3- s3

|

E

|

|

|

L0

|

L1

|

L2

|

L3

|

L4

|

L

|

|

HTB-ZK4.0/20

|

2.2

|

Y90L-2

|

40

|

25

|

100

|

85

|

260

|

260

|

4-M10

|

4-M10

|

4-φ18

|

81

|

160

|

110

|

110

|

97

|

336

|

97

|

308

|

791

|

|

HTB-ZK5.0/30

|

5.5

|

Y132S1-2

|

50

|

40

|

125

|

110

|

320

|

320

|

4-M12

|

4-M12

|

4-φ20

|

98

|

212

|

150

|

110

|

160

|

400

|

160

|

370

|

1042

|

|

HTB-ZK6.5/50

|

15

|

Y160M2-2

|

65

|

50

|

170

|

155

|

330

|

420

|

4-φ18

|

4-φ18

|

4-φ20

|

126

|

310

|

215

|

145

|

184

|

616

|

170

|

480

|

1380

|

|

HTB-ZK8.0/30

|

11

|

Y160M1-2

|

80

|

65

|

180

|

170

|

450

|

450

|

4φ18

|

4-φ18

|

4-φ22

|

110

|

290

|

200

|

147

|

170

|

544

|

170

|

430

|

1254

|

|

HTB-ZK10./35

|

18.5

|

Y160L-2

|

100

|

80

|

210

|

180

|

460

|

460

|

8-φ18

|

4-φ18

|

4-φ23

|

126

|

300

|

200

|

165

|

185

|

680

|

175

|

460

|

1415

|

|

HTB-ZK15.0/25-D

|

30

|

Y200L-4

|

150

|

105

|

270

|

225

|

420

|

536

|

4-φ23

|

4-φ18

|

4-φ24

|

190

|

325

|

280

|

192

|

248

|

700

|

272

|

516

|

1642

|

|

HTB-ZK15.0/25

|

37

|

Y225S-4

|

150

|

105

|

270

|

225

|

420

|

586

|

4-φ23

|

4-φ18

|

4-φ24

|

190

|

350

|

280

|

192

|

248

|

840

|

188

|

516

|

1688

|

|

HTB-ZK15.0/40-M

|

45

|

Y225M-4

|

150

|

106

|

270

|

240

|

510

|

610

|

8-φ23

|

4-φ23

|

4-φ25

|

223

|

370

|

320

|

210

|

250

|

935

|

250

|

550

|

1845

|

About usCentury-old enterprise, global brand

About usCentury-old enterprise, global brand ProductsNational key high-tech enterprise with micro-porous ceramics and structural ceramics as the core

ProductsNational key high-tech enterprise with micro-porous ceramics and structural ceramics as the core Research · InnovationNational key high-tech enterprise, national-level non-metallic materials industry base, Jiangsu Province non-metallic materials engineering technology research center, member of the National Separation Machinery Standardization Technical Committee.

Research · InnovationNational key high-tech enterprise, national-level non-metallic materials industry base, Jiangsu Province non-metallic materials engineering technology research center, member of the National Separation Machinery Standardization Technical Committee. ServiceAdhere to the spirit of craftsmanship and strive to create a century of performance.

ServiceAdhere to the spirit of craftsmanship and strive to create a century of performance. Contact usOur company, in line with its policy of "Healthy Sustainable Development", is willing to cooperate with a wide range of peers both domestically and internationally in terms of technology, economy, and trade, to make a due contribution to environmental protection and energy conservation.

Contact usOur company, in line with its policy of "Healthy Sustainable Development", is willing to cooperate with a wide range of peers both domestically and internationally in terms of technology, economy, and trade, to make a due contribution to environmental protection and energy conservation.

.png)