.jpg)

The company began to develop and manufacture ceramic filters in the 90s of the last century, and in 1997 successfully developed a fully automatic ceramic filter with independent intellectual property rights, breaking the technical blockade of foreign companies and the monopoly of the domestic market. It is the leading unit responsible for drafting national industry standards for ceramic filters and ceramic filter plates.

Product Overview

HTG automatic ceramic filter is a new, high-efficiency, energy-saving, environmentally friendly, high-tech material dewatering equipment integrating microporous ceramics, electromechanical, ultrasonic technology, and automation control. It is a key research project in Jiangsu Province's "Ninth Five-Year Plan", which has passed the national technical appraisal, is listed as a national innovation fund project and a national torch plan project, and has been rated as a national key new product. At present, it is a manufacturing enterprise with a large domestic production scale and filtration area, complete varieties and specifications, and the comprehensive performance of the whole machine has reached the advanced level of similar foreign products.

Through the technological innovation of the core technology ceramic filter plate, vacuum suction system and recoil cleaning system, the key technology of large-scale and super-large ceramic filter machine has been broken. 80m was developed continuously 2 , 100m 2 , 120m 2 , 144m 2 , 180m 2 , 204m 2 , 240m 2 Ceramic filters.

Technical characteristics

High vacuum degree, good dehydration & drying performance of filter cake, clear filtrate, clean working environment, high degree of automation, high production capacity, ultra-low operating and maintenance costs, high energy efficiency and all-round environmental protection system, long service life of ceramic plates, wide application fields.

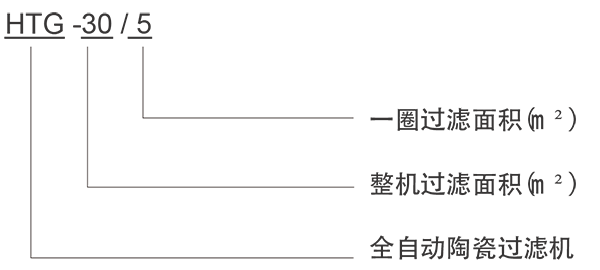

Model description

Filter area selection

1~240m2

技术规格

| Model/ Parameters |

HTG01/1 |

HTG06/3 |

HTG09/3 |

HTG12/3 |

HTG15/3 |

HTG18/3 |

HTG21/3 |

HTG24/3 |

HTG30/3 |

HTG45/3 |

HTG51/3.75 |

HTG45/3.75 |

HTG60/4 |

HTG80/4 |

| Filtration area(m2) |

1 |

6 |

9 |

12 |

15 |

18 |

21 |

24 |

30 |

45 |

51 |

45 |

60 |

80 |

| Installed power (KW) |

6 |

8 |

10 |

11 |

14 |

15 |

15 |

15 |

18 |

22 |

22 |

22 |

30 |

40 |

| Weight(t) |

2.2 |

5.6 |

7.9 |

8.5 |

9.2 |

9.9 |

10.2 |

11.2 |

12.8 |

15.6 |

13.1 |

12 |

18.5 |

24 |

| Length (mm) |

1910 |

3062 |

4170 |

4360 |

4770 |

4780 |

5375 |

5453 |

6318 |

7998 |

6300 |

6100 |

8054 |

9562 |

| Width (mm) |

1900 |

3025 |

2935 |

3200 |

3200 |

3200 |

3200 |

3200 |

3400 |

3410 |

3020 |

3020 |

3150 |

3510 |

| Height (mm) |

1780 |

2750 |

2750 |

2750 |

2750 |

2750 |

2750 |

2750 |

2750 |

2750 |

2720 |

2720 |

3270 |

3233 |

| Model/Parameters |

HTG20/5 |

HTG25/5 |

HTG30/5 |

HTG45/5 |

HTG50/5 |

HTG60/5 |

HTG80/5 |

HTG100/5 |

HTG120/6 |

HTG144/12 |

HTG180/12 |

HTG204/12 |

HTG240/12 |

| Filtration area (m2) |

20 |

25 |

30 |

45 |

50 |

60 |

80 |

100 |

120 |

144 |

180 |

204 |

240 |

| Installed power(KW) |

17 |

18 |

20 |

22 |

22 |

29 |

39 |

43 |

57 |

67 |

114 |

116.8 |

121 |

| Weight (t) |

7.2 |

7.9 |

9.5 |

11.3 |

12.5 |

14 |

18.5 |

23 |

25 |

28.5 |

39 |

42 |

45 |

| Length (mm) |

4470 |

4690 |

4810 |

5470 |

5690 |

6130 |

7253 |

8094 |

9437 |

7260 |

9670 |

10470 |

11670 |

| Width (mm) |

3510 |

3510 |

3510 |

3510 |

3510 |

3510 |

3510 |

3510 |

3565 |

5330 |

5330 |

5330 |

5330 |

| Height (mm) |

2980 |

2980 |

3035 |

3035 |

3035 |

3035 |

3035 |

3035 |

3295 |

4786 |

4786 |

4786 |

4786 |

Ceramic filter plate

Our company is a national key high-tech enterprise specializing in the research and development and production of microporous ceramics and structural ceramics, and is also a well-known backbone enterprise in the domestic industrial ceramic manufacturing industry, with advanced R&D equipment and strong R&D strength. The new microporous ceramic filter plate is the core component of the ceramic filter machine. The renewable ceramic filter plate and the microporous ceramic filter plate that can be reused and the microporous ceramic filter plate that is resistant to microfluorine and PH>8.5-12 media have better expanded the application field of ceramic filters.

Technical advantages

High production capacity, long service life, wide application field.

Ceramic filter plate selection

1m2 2m2 3m2 3.75m2 4m2 5m2 6m2 8m2 12m2

Filter precision selection

0.8-1μm 2μm 5μm

(1)(1).jpg)

Accessories

User site

.jpg)

About usCentury-old enterprise, global brand

About usCentury-old enterprise, global brand ProductsNational key high-tech enterprise with micro-porous ceramics and structural ceramics as the core

ProductsNational key high-tech enterprise with micro-porous ceramics and structural ceramics as the core Research · InnovationNational key high-tech enterprise, national-level non-metallic materials industry base, Jiangsu Province non-metallic materials engineering technology research center, member of the National Separation Machinery Standardization Technical Committee.

Research · InnovationNational key high-tech enterprise, national-level non-metallic materials industry base, Jiangsu Province non-metallic materials engineering technology research center, member of the National Separation Machinery Standardization Technical Committee. ServiceAdhere to the spirit of craftsmanship and strive to create a century of performance.

ServiceAdhere to the spirit of craftsmanship and strive to create a century of performance. Contact usOur company, in line with its policy of "Healthy Sustainable Development", is willing to cooperate with a wide range of peers both domestically and internationally in terms of technology, economy, and trade, to make a due contribution to environmental protection and energy conservation.

Contact usOur company, in line with its policy of "Healthy Sustainable Development", is willing to cooperate with a wide range of peers both domestically and internationally in terms of technology, economy, and trade, to make a due contribution to environmental protection and energy conservation.

.jpg)

(1)(1).jpg)

.jpg)