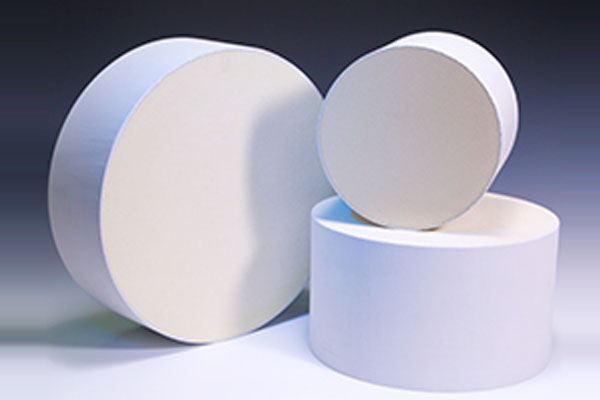

The external pressure filtration device adopts an asymmetrical ceramic membrane made of inorganic ceramic materials through a special process as the filter element, with a pore size of 0.2-10μm, with good chemical stability, acid, alkali and organic solvent resistance, high temperature resistance, strong antimicrobial ability, high separation efficiency, high mechanical strength, long service life and other advantages, suitable for high temperature, high pressure, strong corrosion of organic membranes can not be used under working conditions, can be widely used in petroleum, chemical, medicine, environmental protection and other industries of filtration, purification, sterilization, etc. Process of removing impurities.

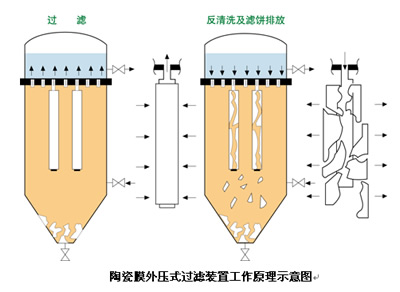

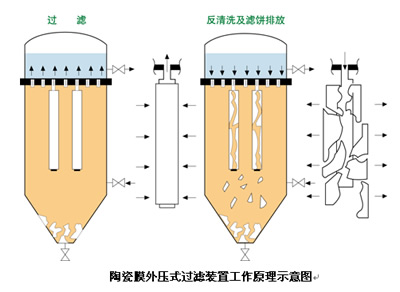

The working principle of ceramic membrane external pressure filtration device

1. Filtration:

The device adopts the method of surface filtration mechanism filter cake filtration, during filtration, the filter material is driven into the filter with a pump, and the clear liquid enters the collection pipe through the pore in the support body through the ceramic membrane, and the solids in the material are intercepted on the surface of the membrane to form a filter cake.

2. Backflush and slag discharge:

Relying on compressed air to drive the clear liquid for backflush, the liquid instantly reverses the flow to remove the filter cake from the surface of the membrane and sink to the bottom of the filter.

3. Continuous and reliable operation:

Filtration, recoil, and slag discharge are controlled by PLC programs, and the cycle is repeated to realize the continuous and reliable operation of the ceramic membrane filter.

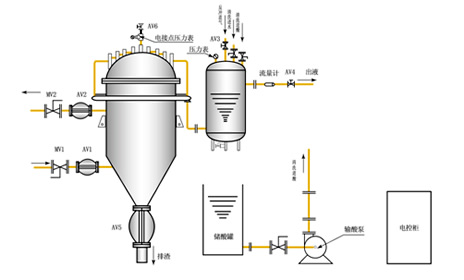

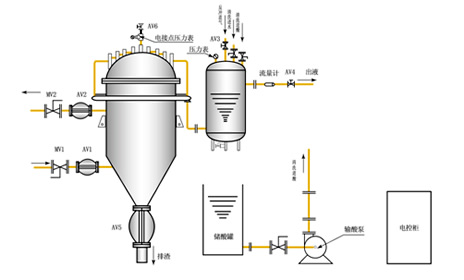

Process flow diagram of ceramic membrane external pressure filtration device

Applications

Petrochemical

Precision filtration and purification of chemical solutions; catalyst recovery and enrichment; product purification and grading concentration; waste oil purification treatment and regeneration; Oilfield water injection and purification treatment.

Coal

Introduction to the application of water filtration in coal mines; Introduction to coal washing water filtration applications

Biopharmaceuticals

Antibiotics: bacillus sulfate, cephalosporin, inosine, erythromycin, etc.; Fermented organic acids: lactic acid, citric acid, etc.; Amino acids: lysine, glutamic acid. phenylalanine, glycine, etc.; Vitamins: vitamin C, vitamin B2, vitamin B12; Proprietary Chinese medicines: various single-formula compound oral liquids, injections, traditional Chinese medicine extracts, etc.; Enzyme preparations: lipidase, protease, etc.; Biochemical products: thymuspeptide, interferon, vaccines, etc.; Natural product extracts: allium root, soy peptides, natural colors, tea polyphenols, etc

Food and beverage

Dairy: bovine colostrum, yogurt, whey protein sterilization and concentration, protein standardization; Alcohol: wine, beer, fruit wine, rice wine, etc.; Fruit tree juice: apple juice, cranberry juice, pineapple juice, etc.; Sugar: beet sugar, sucrose, starch sugar, etc.; Brewing products: soy sauce, vinegar; Tea deep processing: tea drinks, catechu, etc.; Soybean deep processing: polypeptides, isoflavones, oligosaccharides Marine animal and plant products deep processing

Environmentally friendly wastewater

Cold-rolled emulsion wastewater from steel plants; banknote printing and printing wastewater; Oily emulsion wastewater in the automotive industry; cutting fluid and degreasing fluid wastewater in the machining industry; alkali refining and washing wastewater in the oil industry; the oil industry refining and washing wastewater; industrial acid-alkali wastewater; high concentration COD/BOD wastewater such as dyes and bleaching and dyeing; wastewater containing heavy metals and radioactive components; Wastewater from the electroplating industry; Grinding and microelectronic wastewater

Mother liquor filtration effect in different industries

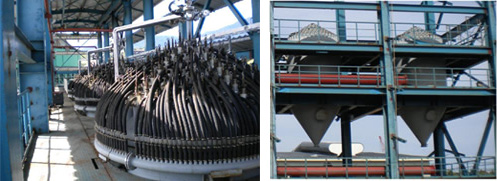

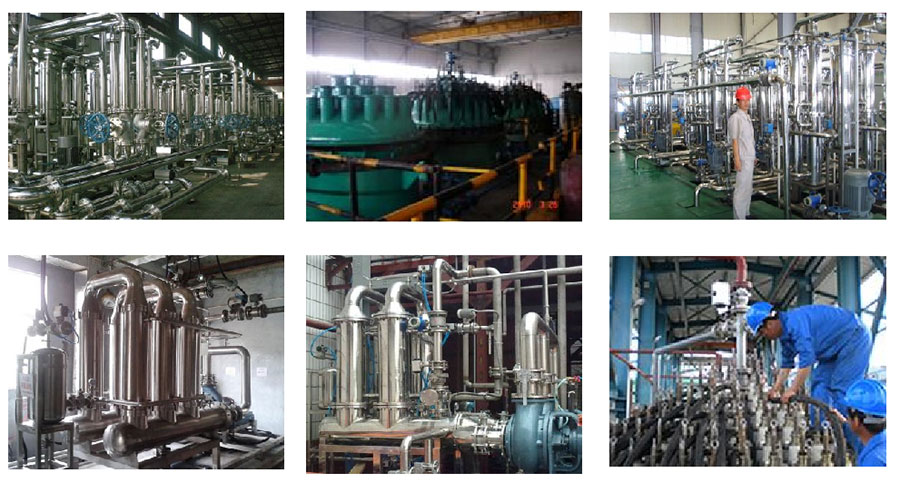

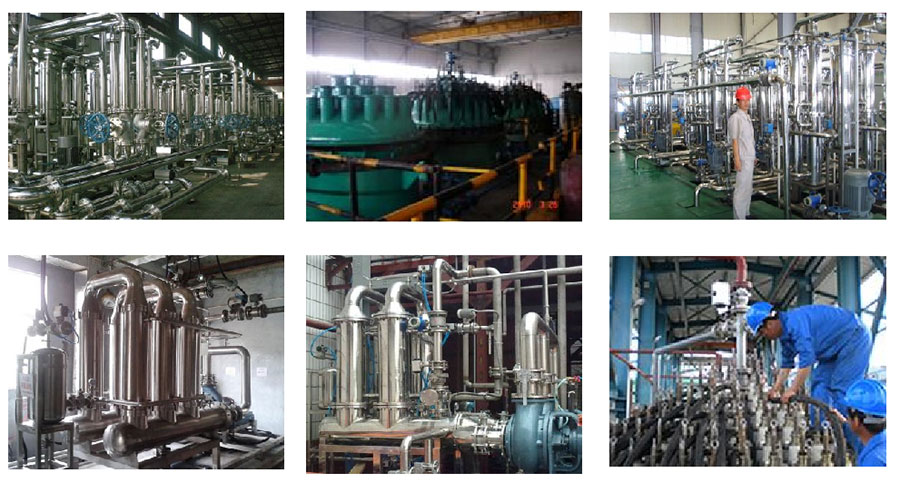

User site

About usCentury-old enterprise, global brand

About usCentury-old enterprise, global brand ProductsNational key high-tech enterprise with micro-porous ceramics and structural ceramics as the core

ProductsNational key high-tech enterprise with micro-porous ceramics and structural ceramics as the core Research · InnovationNational key high-tech enterprise, national-level non-metallic materials industry base, Jiangsu Province non-metallic materials engineering technology research center, member of the National Separation Machinery Standardization Technical Committee.

Research · InnovationNational key high-tech enterprise, national-level non-metallic materials industry base, Jiangsu Province non-metallic materials engineering technology research center, member of the National Separation Machinery Standardization Technical Committee. ServiceAdhere to the spirit of craftsmanship and strive to create a century of performance.

ServiceAdhere to the spirit of craftsmanship and strive to create a century of performance. Contact usOur company, in line with its policy of "Healthy Sustainable Development", is willing to cooperate with a wide range of peers both domestically and internationally in terms of technology, economy, and trade, to make a due contribution to environmental protection and energy conservation.

Contact usOur company, in line with its policy of "Healthy Sustainable Development", is willing to cooperate with a wide range of peers both domestically and internationally in terms of technology, economy, and trade, to make a due contribution to environmental protection and energy conservation.