1, Product Introduction

HTB-Y series corrosion-resistant and wear-resistant submersible pump, its flow parts are made of ultra-high molecular weight polyethylene (UHMWPE) with excellent performance, which is called a novel engineering plastic for pumps in the international community. Its outstanding advantages are: it has excellent wear resistance, impact resistance, and anti-creep properties among all engineering plastics, and it also has very good corrosion resistance, suitable for conveying acidic, alkaline slurry and acidic, alkaline clear liquid in the range of -20~90℃.

This series of pumps have been mass-produced for more than ten years, and have been used by more than 600 users and more than 2000 positions. Its temperature resistance, corrosion resistance, mechanical stability, wear resistance and the economy of operation costs have been recognized by users. Therefore, this product is a performance-stable, technologically mature, user-friendly, and standardized corrosion-resistant pump product, and is an ideal alternative to precious metal pumps.

2, Application

●Non-ferrous metal wet process smelting industry: → Suitable for the transportation of various acids, alkalis, corrosive ore pulp, electrolytes, waste acid, and sewage in the wet process smelting of lead, zinc, gold, silver, copper, manganese, cobalt, rare earth, etc.

●Phosphoric acid fertilizer industry: Transportation of dilute acid, mother liquor, fluorosilic acid containing silica gel, phosphate slurry and other media.

●Water treatment and environmental protection industry: Can transport various impure sewage.

●Pesticides, dyes, and fine chemical industry: Can transport acidic, alkaline liquids containing solvents, mixed acids, and slurry containing solvents and alkaline slurry.

●Widely used in metallurgy, chemical industry, petroleum, synthetic fiber, sewage treatment and other industrial departments, to transport various corrosive liquids or corrosive media containing different particles.

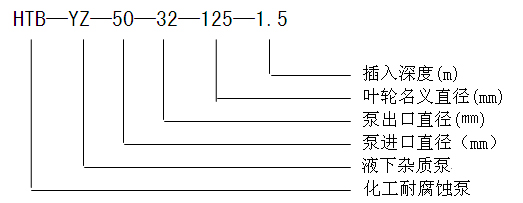

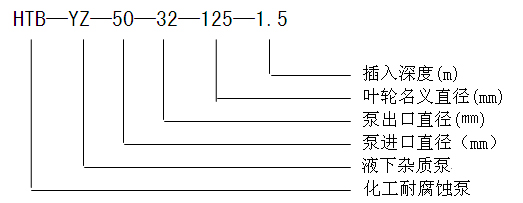

3, Model Description

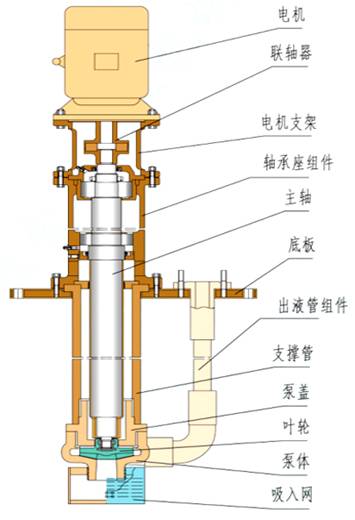

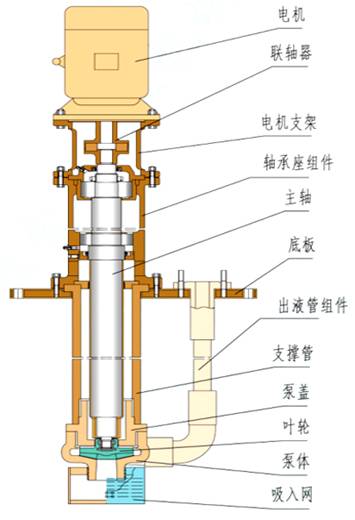

4, Structural pattern

5, Detailed parameters

Parameter \ Model |

impeller specifications |

Rated speed 2900 rpm |

Rated speed 1450 rpm |

Weight

(kg) |

Flow rate Q

(m³/h) |

Head H

(m) |

Motor power N

(Kw) |

Flow rate Q

(m³/h) |

Head H

(m) |

Motor power N

(Kw) |

Y50-32-125 |

Standard

|

8 |

22 |

3 |

|

|

|

|

12.5 |

20 |

|

|

|

16 |

16 |

|

|

|

A |

5 |

15 |

2.2 |

|

|

|

9 |

12 |

|

|

|

12 |

8 |

|

|

|

Y50-32-160 |

Standard

|

8 |

33 |

5.5 |

|

|

|

|

12.5 |

32 |

|

|

|

16 |

29 |

|

|

|

Y65-50-160 |

Standard

|

20 |

33.5 |

7.5 |

|

|

|

|

25 |

32 |

|

|

|

30 |

29 |

|

|

|

A |

10 |

25 |

5.5 |

|

|

|

15 |

23.5 |

|

|

|

20 |

21.5 |

|

|

|

Y80-65-160 |

Standard

|

40 |

34 |

11 |

|

|

|

|

50 |

32 |

|

|

|

60 |

28.5 |

|

|

|

Y65-40-200 |

Standard

|

15 |

51.5 |

15 |

|

|

|

|

25 |

50 |

|

|

|

30 |

46 |

|

|

|

Y80-50-200 |

Standard

|

40 |

53 |

22 |

|

|

|

|

50 |

50 |

|

|

|

60 |

45 |

|

|

|

Y100-80-160 |

|

100 |

32 |

22 |

|

|

|

|

Y150-125-315 |

Standard

|

|

|

|

130 |

35 |

45 |

|

| |

|

200 |

32 |

| |

|

240 |

28 |

A |

|

|

|

85 |

28.5 |

30 |

|

| |

|

120 |

26 |

| |

|

150 |

25 |

6, Pump external and mounting dimensions

.png)

Model |

L1 |

L |

Base plate |

Export flange |

D |

D1 |

n1-φd1 |

D2 |

D3 |

D4 |

n2-d2 |

YZ50-32-125 |

162 |

225 |

580 |

540 |

12-φ18 |

100 |

78 |

32 |

4-M12 |

YZ50-32-160 |

210 |

330 |

700 |

650 |

16-φ18 |

|

|

|

|

YZ65-50-160 |

200 |

320 |

|

|

|

125 |

105 |

50 |

4-M16 |

YZ65-40-200 |

220 |

340 |

110 |

85 |

40 |

4-M16 |

YZ80-65-160 |

220 |

340 |

145 |

125 |

65 |

4-M16 |

YZ80-50-200 |

220 |

340 |

125 |

105 |

50 |

4-M16 |

YZ100-80-160 |

195 |

315 |

160 |

132 |

80 |

4-M16 |

YZ150-125-315 |

310 |

525 |

|

|

|

240 |

210 |

125 |

8-M16 |

7, Instructions for use

a) During handling and installation, the bearing housing of the pump should be the point of force, as the support pipe is made of glass, and it is strictly prohibited to use the support pipe as the support point for lifting.

b) The main shaft of the submersible pump is a slender shaft structure, and there may be slight bending deformation during long-distance transportation (the feeling of uneven tightness when turning the coupling). Do not start the pump immediately after installation; it is recommended to place it for 24 hours to restore it to normal before testing.

c) The pump should be installed vertically and should not have a significant tilt. In general, the base plate should be calibrated with a level, which is particularly important for submersible pumps.

d) A straight pipe should be installed at the outlet, and it is strictly prohibited to directly install a弯pipe; a flow control valve should also be installed to operate the pump at the specified flow rate.

e) When starting the pump for the first time, pay attention to the direction of rotation. The rotation is clockwise from the motor pump shell (from top to bottom), and it is strictly prohibited to reverse it.

f) Before starting the pump, check the bearings to ensure that there is sufficient grease to prevent the bearings from overheating. Pay attention to regularly adding oil to the bearing housing during the operation of the pump, and the temperature rise of the bearings should not exceed 50 degrees, with the limit temperature not exceeding 80 degrees.

g) It is a normal phenomenon for the pump to have slight vibration during operation. However, to reduce the vibration, the foundation should have good vibration absorption properties while maintaining a level installation base.

h) Adjust the outlet valve to make the pump work as much as possible under the rated working conditions. It is not allowed to use it for a long time at a very small or very large flow rate, which may affect the service life of the pump.

i) After starting the pump, pay attention to the three-phase current of the motor, which should not exceed the rated value, and make a record as the basis for judging the next start.

j) When the pump starts, the liquid level should not be lower than the starting liquid level.

k) Sometimes, when the pump is working, liquid will spray out from the round hole at the bottom of the support pipe. This is normal, especially when the flow rate is small, the liquid will spray out more and more urgently.

l) It is necessary to regularly check whether the filter screen is unobstructed and whether particles block the suction net holes.

m) When stopping the pump, the outlet valve should be closed first, and then the motor should be stopped.

About usCentury-old enterprise, global brand

About usCentury-old enterprise, global brand ProductsNational key high-tech enterprise with micro-porous ceramics and structural ceramics as the core

ProductsNational key high-tech enterprise with micro-porous ceramics and structural ceramics as the core Research · InnovationNational key high-tech enterprise, national-level non-metallic materials industry base, Jiangsu Province non-metallic materials engineering technology research center, member of the National Separation Machinery Standardization Technical Committee.

Research · InnovationNational key high-tech enterprise, national-level non-metallic materials industry base, Jiangsu Province non-metallic materials engineering technology research center, member of the National Separation Machinery Standardization Technical Committee. ServiceAdhere to the spirit of craftsmanship and strive to create a century of performance.

ServiceAdhere to the spirit of craftsmanship and strive to create a century of performance. Contact usOur company, in line with its policy of "Healthy Sustainable Development", is willing to cooperate with a wide range of peers both domestically and internationally in terms of technology, economy, and trade, to make a due contribution to environmental protection and energy conservation.

Contact usOur company, in line with its policy of "Healthy Sustainable Development", is willing to cooperate with a wide range of peers both domestically and internationally in terms of technology, economy, and trade, to make a due contribution to environmental protection and energy conservation.

.png)