1. Overview

The HTB-ZL type series evaporation forced circulation pump (chemical axial flow pump) is one of the types of corrosion-resistant pumps in our company's HTB type series. Since 1957, our company has been researching non-metallic pump machines, and the application fields of forced circulation pumps have been extended from the original caustic evaporation to: phosphatic ammonia, phosphoric acid, vacuum salt making, alcohol, lactic acid, alumina, rutile, titanium white, calcium chloride, ammonium chloride, refrigerant, molten salt, polyvinyl chloride, waste acid concentration and other industries.

The HTB-ZL type series forced circulation pump of our company is developed and manufactured based on the second-generation product, drawing on the advantages of similar foreign products, and consulting the opinions of engineering and technical personnel who have been engaged in evaporation design for a long time in professional design institutes. The HTB-ZL type series has three forms of installation: installation on the ground, suspension, and floating on the pool surface. Sealing structure: packing seal, auxiliary impeller + combination mechanical seal, combination mechanical seal, etc.

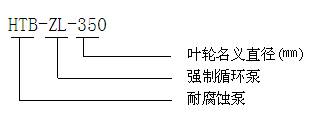

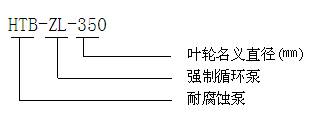

2. Model Description

3, Detailed parameters

|

Pump model

|

Flow rate (m3/h) |

Range (m) |

Motor power (Kw) |

RPM (revolutions per minute) |

| HTB-ZL-250 |

300 |

2.5 |

7.5 |

980 |

| HTB-ZL-300 |

520 |

3 |

11 |

980 |

| HTB-ZL-350 |

1350 |

4 |

37 |

980 |

| HTB-ZL-450 |

2200 |

4 |

55 |

980 |

| HTB-ZL-500 |

2650 |

4 |

75 |

740 |

| HTB-ZL-550 |

4000 |

4 |

110 |

750 |

Note: The data in the table is the performance of clean water at room temperature, and it should be converted according to the actual situation when selecting.

If the selected parameters are not within the scope of this table, our factory can change the size of the impeller or other methods to achieve it.

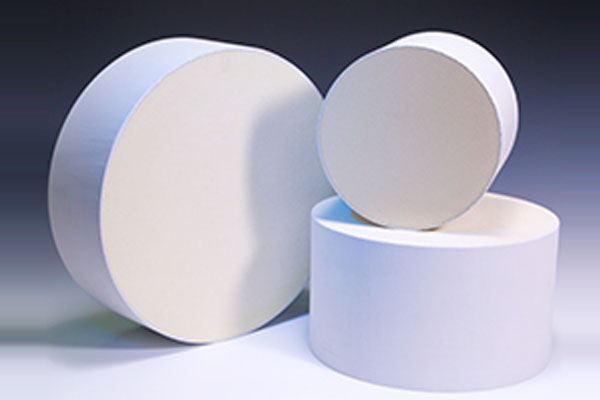

4, Structural Description

The forced circulation pump is a horizontal corrosion-resistant axial flow pump, and its flow parts are made of steel lined with plastic or ceramic and special alloy, and the shaft seal is a combination of a付叶 wheel dynamic seal and a mechanical seal in structure, ensuring that there is no leakage of liquid when working and at rest. The mechanical seals used in the shaft seal have two types of structures: single-end face and double-end face, which can be selected by the user. Most of the parts of the single-end face and double-end face mechanical seals are universal, and both structures require the addition of flushing fluid and cooling water. For corrosive, high pressure and concentration occasions, such as the evaporation section of caustic soda, it is recommended to use a double-end face structure. In order to facilitate the installation and inspection of the user, the mechanical seal housing adopts a split form. The claw-type coupling is driven by a rubber block, which has a certain shock absorption and buffer effect. Compared with the same type of domestic products, this pump has a compact structure, stable operation, light weight and small footprint.

5, Pump Installation

5.1 The pump and the electric motor must be installed on the same shaft line, and the deviation must not exceed 0.2㎜.

5.2 The connecting pipeline of the pump should be reasonably equipped with supports.

5.3 Due to the temperature difference caused by the start and stop of the pump, the pipeline expansion and contraction should be installed with expansion joints at the inlet and outlet pipelines of the pump.

6, Pump Operation and Maintenance

6.1 Check the oil level frequently, and add lubricating oil when it reaches the lower limit.

6.2 After installation, if it is necessary to check and adjust the mechanical seal part, the shell can be disassembled for inspection and adjustment without moving the pump body and bearing housing, allowing the horizontal split shell to be disassembled.

6.3 When replacing the impeller or checking the interior of the pump body, the fixing screws of the motor can be loosened to pull out the motor, and then the small screws of the back cover can be removed, and then the rotating part can be taken out.

6.4 Before the first start-up, the entire system must be flushed to remove debris. Whether the cooling water and flushing fluid at the sealed parts and bearing boxes are unobstructed, and whether the pressure of the flushing fluid is 0.5-1 kg/㎠2 higher than the system pressure before the pump is put into operation should be strictly checked.

6.5 Check the correct direction of the impeller by energizing the motor in bursts, and strictly prohibit reverse rotation.

6.6 If there is any abnormal vibration or noise in the pump body, the pump should be immediately stopped for inspection.

6.7 Check the temperature rise of the bearings of the pump and motor frequently, and the maximum temperature should not exceed 75℃.

6.8 The lubricating oil of the bearings should be replaced regularly, generally once every about 4000 hours of operation.

6.9 Regularly carry out pre-inspection on the main vulnerable parts of the pump, such as the impeller, mechanical seal, bearings, and oil seals, etc. If serious wear and corrosion are found, they should be replaced in time.

6.10 If the system needs to be shut down for a short time, the pump should continue to operate to prevent the precipitation of crystallization, and if it is shut down for a long time, the pump should be cleaned to remove the remaining corrosive fluid.

About usCentury-old enterprise, global brand

About usCentury-old enterprise, global brand ProductsNational key high-tech enterprise with micro-porous ceramics and structural ceramics as the core

ProductsNational key high-tech enterprise with micro-porous ceramics and structural ceramics as the core Research · InnovationNational key high-tech enterprise, national-level non-metallic materials industry base, Jiangsu Province non-metallic materials engineering technology research center, member of the National Separation Machinery Standardization Technical Committee.

Research · InnovationNational key high-tech enterprise, national-level non-metallic materials industry base, Jiangsu Province non-metallic materials engineering technology research center, member of the National Separation Machinery Standardization Technical Committee. ServiceAdhere to the spirit of craftsmanship and strive to create a century of performance.

ServiceAdhere to the spirit of craftsmanship and strive to create a century of performance. Contact usOur company, in line with its policy of "Healthy Sustainable Development", is willing to cooperate with a wide range of peers both domestically and internationally in terms of technology, economy, and trade, to make a due contribution to environmental protection and energy conservation.

Contact usOur company, in line with its policy of "Healthy Sustainable Development", is willing to cooperate with a wide range of peers both domestically and internationally in terms of technology, economy, and trade, to make a due contribution to environmental protection and energy conservation.