1, Product Introduction

The HTB-ZK-M series of low-speed engineering plastic pumps are single-stage, single-suction, suspended centrifugal pumps. They are carefully designed based on the technology of our company's HTB series horizontal pumps and the advantages of domestic and foreign centrifugal pump structures, and they use a jacketed structure.

Compared with the HTB series of horizontal pumps, this pump has many advantages: the pump's impeller and pump body are more wear-resistant and durable due to the low-speed design, resulting in a longer service life and more stable pump operation with lower noise; moreover, since the pump body adopts a jacketed structure, only the plastic pump body needs to be replaced when the pump body wears out, thus saving maintenance costs; the pump also uses our company's newly developed Y4 type of integral hard-to-hard mechanical seal, which not only provides more reliable sealing and a longer service life but also, due to its closed cooling structure, does not produce acid mist like ordinary mechanical seals during operation, protecting the environment from corrosion.

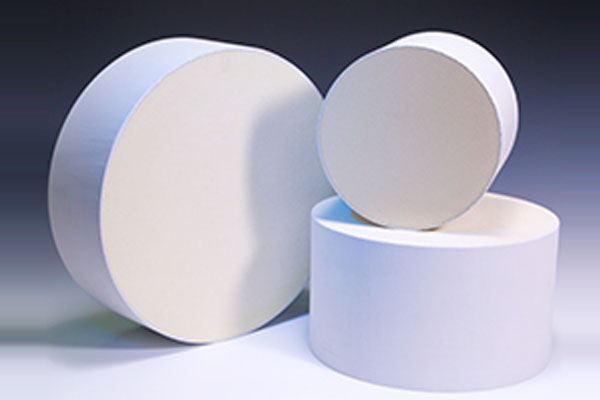

The pump's flow components are made of modified ultra-high molecular weight polyethylene through mold pressing. This material is the latest generation of engineering materials for pump use internationally, and its outstanding advantage is that it has excellent wear resistance among all plastics, as well as impact resistance (especially low-temperature impact resistance), creep resistance (resistance to environmental stress cracking), and very good corrosion resistance.

Therefore, this pump is especially suitable for working positions with particulate corrosive media.

2, Application Range

This pump is mainly used in various chemical industries, non-ferrous metal smelting (gold, silver, copper, aluminum, zinc, cobalt, nickel, etc.), black metal (steel acid pickling, manganese industry), chemical fibers, titanium white, rare earths, rare metals, pesticides, phosphate fertilizers, citric acid, inorganic salts, paper making, desulfurization and environmental protection, wastewater treatment, etc.

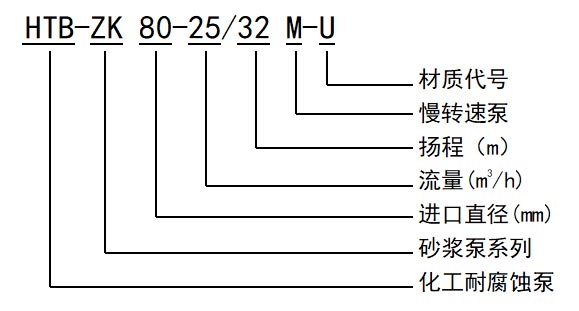

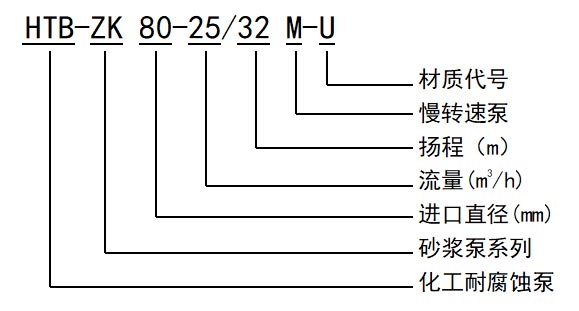

3, Model Description 4, Structural Type 5, Detailed Parameters

4、 Structural type

5、 Detailed parameters

|

Parameter \ Model

|

impeller specifications |

Rated speed 1450 rpm |

Vaporization

Margin

(m) |

Weight

(kg) |

Flow rate Q

(m3/h) |

Head H

(m) |

Motor power N

Medium specific gravity

(Kw) |

Efficiency η

% |

| HTB-ZK40-5/5M-U |

Standard |

4 |

5.5 |

1.1 |

30 |

2.4 |

60 |

| 5 |

5 |

| 6 |

4 |

| HTB-ZK50-10/7.5M-U |

Standard |

5 |

8 |

1.5 |

38 |

2.5 |

110

|

| 10 |

7.5 |

| 12.5 |

7 |

| HTB-ZK50-12.5/20M-U |

Standard |

9.5 |

21.3 |

3 |

28 |

2.8 |

120 |

| 12.5 |

20 |

33 |

| 16 |

19 |

34.5 |

| HTB-ZK65-20/30M-U |

Standard |

12.5 |

32 |

7.5 |

20 |

3 |

250 |

| 20 |

30 |

25 |

| HTB-ZK80-25/32M-U |

Standard |

25 |

32 |

11 |

34 |

3 |

300 |

| 30 |

30 |

38 |

| 35 |

30 |

40 |

| 40 |

30 |

42 |

| HTB-ZK80-45/32M-U |

Standard |

40 |

35 |

15 |

40 |

3 |

330 |

| 45 |

32 |

42 |

| 50 |

30 |

45 |

| HTB-ZK65-13/45M-U |

Standard |

20 |

40 |

15 |

20 |

3 |

457 |

| 13 |

45 |

18 |

| HTB-ZK65-15/55M-U |

Standard |

15 |

55 |

18.5 |

18 |

3 |

470 |

| 20 |

50 |

24 |

| HTB-ZK65-30/55M-U |

Standard |

30 |

55 |

22 |

29 |

3 |

490 |

| HTB-ZK80-50/50M-U |

Standard |

50 |

50 |

22 |

37 |

3 |

490 |

| HTB-ZK125-100/50M-U |

Standard |

100 |

50 |

37 |

50 |

5.5 |

|

6, Pump external and mounting dimensions Mounting external dimensions table

Installation Outline Dimensional Table

| Model |

Power

(KW) |

Motor-driven |

Installation dimensions |

| d1 |

d2 |

D01 |

D02 |

D1 |

D2 |

B1 |

B2 |

n1-s1 |

n2-s2 |

n3-s3 |

E |

h1 |

h2 |

L0 |

L1 |

L2 |

L3 |

L4 |

L5 |

L |

| ZK65-20/30M-U |

7.5 |

Y132M-4 |

65 |

50 |

160 |

125 |

200 |

160 |

460 |

460 |

4-M16 |

4-M12 |

4-φ23 |

174.5 |

345 |

240 |

106 |

75 |

755 |

205 |

195 |

1155 |

1188 |

| ZK80-25/32M-U |

11 |

Y160M-4 |

80 |

50 |

160 |

125 |

200 |

160 |

460 |

460 |

4-M16 |

4-M12 |

4-φ23 |

174.5 |

345 |

240 |

106 |

75 |

755 |

205 |

195 |

1155 |

1250 |

| ZK80-45/32M-U |

15 |

Y160L-4 |

80 |

50 |

160 |

125 |

200 |

160 |

460 |

460 |

4-M16 |

4-M12 |

4-φ23 |

174.5 |

345 |

240 |

106 |

75 |

755 |

205 |

195 |

1155 |

1295 |

| ZK65-13/45M-U |

15 |

Y160L-4 |

65 |

50 |

160 |

125 |

210 |

160 |

510 |

460 |

4-M16 |

4-M12 |

4-φ23 |

228 |

400 |

300 |

120 |

63 |

790 |

240 |

200 |

1230 |

1317 |

| ZK65-15/55M-U |

18.5 |

Y180M-4 |

65 |

50 |

160 |

125 |

210 |

160 |

510 |

460 |

4-M16 |

4-M12 |

4-φ23 |

228 |

400 |

300 |

120 |

75 |

790 |

240 |

200 |

1230 |

1361 |

| ZK65-30/55M-U |

22 |

Y180L-4 |

65 |

50 |

160 |

125 |

210 |

160 |

510 |

460 |

4-M16 |

4-M12 |

4-φ23 |

228 |

400 |

300 |

120 |

75 |

790 |

240 |

200 |

1230 |

1401 |

| ZK80-50/50M-U |

22 |

Y180L-4 |

80 |

50 |

160 |

125 |

210 |

160 |

510 |

460 |

4-M16 |

4-M12 |

4-φ23 |

228 |

400 |

300 |

120 |

75 |

790 |

240 |

200 |

1230 |

1401 |

About usCentury-old enterprise, global brand

About usCentury-old enterprise, global brand ProductsNational key high-tech enterprise with micro-porous ceramics and structural ceramics as the core

ProductsNational key high-tech enterprise with micro-porous ceramics and structural ceramics as the core Research · InnovationNational key high-tech enterprise, national-level non-metallic materials industry base, Jiangsu Province non-metallic materials engineering technology research center, member of the National Separation Machinery Standardization Technical Committee.

Research · InnovationNational key high-tech enterprise, national-level non-metallic materials industry base, Jiangsu Province non-metallic materials engineering technology research center, member of the National Separation Machinery Standardization Technical Committee. ServiceAdhere to the spirit of craftsmanship and strive to create a century of performance.

ServiceAdhere to the spirit of craftsmanship and strive to create a century of performance. Contact usOur company, in line with its policy of "Healthy Sustainable Development", is willing to cooperate with a wide range of peers both domestically and internationally in terms of technology, economy, and trade, to make a due contribution to environmental protection and energy conservation.

Contact usOur company, in line with its policy of "Healthy Sustainable Development", is willing to cooperate with a wide range of peers both domestically and internationally in terms of technology, economy, and trade, to make a due contribution to environmental protection and energy conservation.