1, Overview

In the 1990s, our company undertook the research and development of the national major technological equipment project "HTB Series Modified Ultra High Molecular Weight Polyethylene Pump" and passed the national appraisal in 1998. This pump absorbed the advanced technology of a series of corrosion-resistant pumps at home and abroad, and was specially designed for petrochemical, non-ferrous metal smelting, chlor-alkali and sulfur-phosphorus industries. The flow parts are generally made of steel lined ultra high molecular weight polyethylene (UHMWPE). This material is the new generation of pump用 corrosion-resistant and wear-resistant engineering plastics in the world at present. The pump's operating temperature is less than 95℃, and it can be widely used in metallurgy, chemical industry, petroleum, synthetic fiber, sewage treatment and other industrial departments to transport various corrosive liquids or corrosive media containing different fine particles.

2, Advantages

This pump is developed and designed by our company based on the advanced technology of similar products at home and abroad, in accordance with ISO2858/5199 international standards. It adopts CAD modular optimization structure design, and the pump structure is novel and reliable with good interchangeability of parts. The overall heavy-duty suspended bearing housing bracket, thin oil lubricated ball bearings, maze seals, good coaxiality of the bearing bracket, high stability, good rigidity, and small deformation. The impeller has two types: closed and semi-open. The closed impeller has strong adaptability to the working condition, high efficiency, low cavitation value, and the semi-open impeller is suitable for conveying liquids with a large concentration of solid particles. The structure is advanced, the effect is better, the working efficiency is 5% to 8% higher than that of the old domestic models, the structure is compact, and the maintenance is convenient. The flow parts are made of engineering plastics, and its most prominent advantage is its excellent wear resistance, impact resistance (especially low-temperature impact resistance), creep resistance (resistance to environmental stress cracking), and extremely good corrosion resistance.

3, Applications

Smelting industry of various corrosive slurries; dilute acid, mother liquor, wastewater, seawater, fluorosilic acid containing silicagel, phosphate slurry; Non-ferrous smelting industry: especially suitable for various acids, corrosive slurries, slurry (filter press) for electrolyte, wastewater and other media transportation. Chemical and other enterprises: various sulfuric acid, hydrochloric acid, alkaline, oil clear liquid or slurry post. Titanium white, iron red powder production, various dyes, pigments production, non-metallic mineral processing and other industries. Chlor-alkali industry: hydrochloric acid, liquid alkali, electrolyte, etc. Water treatment industry: pure water, high-purity water, wastewater. Steel enterprises: sulfuric acid, hydrochloric acid post of pickling system, wastewater with impurities. Wet desulfurization circulating pump: can be used at the same time alkaline, acidic, corrosive post.

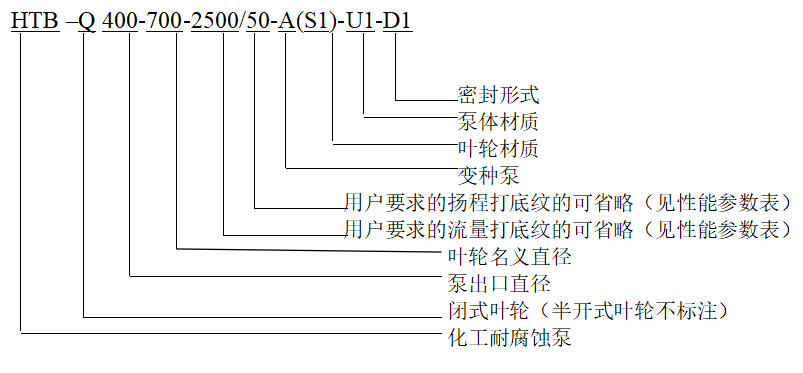

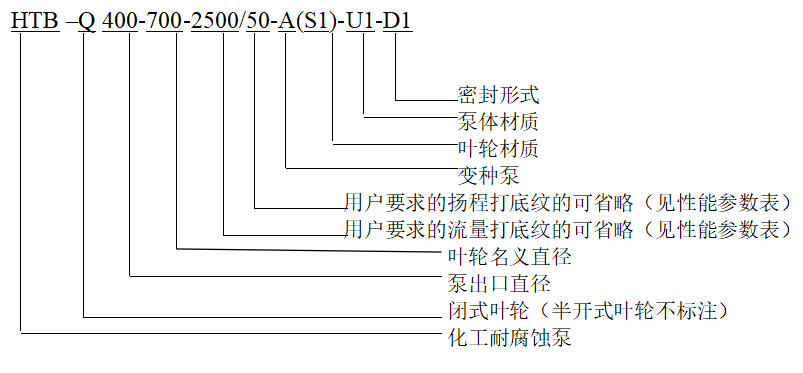

4, Model description

Impeller material code

| Material |

Ultra-high molecular weight polyethylene |

Modified rubber and plastic |

Fluoride alloy |

Polyvinylidene fluoride |

Polyether chloride |

Stainless steel |

| Corrosion resistance and wear resistance |

Heat resistant and wear-resistant |

Corrosion resistance |

| Code name |

S |

S1 |

S3 |

S2 |

S4 |

S5 |

S6 |

G |

| Note |

U-shaped pump not marked |

|

|

|

|

|

|

|

Pump body material code

| Material |

Ultra-high molecular weight polyethylene |

Modified rubber and plastic |

Fluoride alloy |

Polyvinylidene fluoride |

Polyether chloride |

Stainless steel |

| Corrosion resistance and wear resistance |

Heat resistant and wear-resistant |

Corrosion resistance |

| Code name |

U |

U1 |

U3 |

U 2 |

U 4 |

U 5 |

U 6 |

G |

| Note |

|

|

|

|

|

|

|

|

Sealed form

| Sealed form |

Mechanical seal |

Packing seal |

Oil seal; seal |

Hard on hard; sealed |

Double-end face seal |

Modular mechanical seal |

Pay power seal |

| Packing seal |

Oil seal seal |

Oil seal seal |

Mechanical seal |

| Code name |

J |

T |

Y1 |

Y2 |

Y3 |

Y4 |

D |

D1 |

D2 |

D3 |

| Note |

Matching clear liquid pump |

|

|

Add coolant |

Add coolant |

Add coolant |

|

|

No cooling water added |

Add coolant |

5, Performance curve (see also)

6, detailed parameters

|

Parameters / Model

|

impeller specifications |

Rated speed 2900 rpm |

Rated speed 1450 rpm |

Bearing housing |

NPSH margin (m) |

Weight (kg) |

| Flow rate Q (m3/h) |

Discharge head H (m) |

Motor power

N medium specific gravity (kW) (kW) |

Efficiencyη % |

Flow rate Q (m3/h) |

Range H (m) |

Motor power

N medium specific gravity (kW) (kW) |

Efficiencyη % |

| HTB32 -125 |

Standard |

7.5 |

22 |

2.2 |

40 |

3.75 |

5.5 |

0.55 |

35 |

K0 |

4.0 |

90 |

| 12.5 |

20 |

6.3 |

5.0 |

| 15.0 |

18 |

7.5 |

4.5 |

| A |

5 |

20 |

2.2 |

27 |

|

|

|

|

| 10 |

15 |

2.2 |

29 |

|

|

|

|

| B |

7.5 |

16 |

1.5 |

28 |

|

|

|

|

| C |

15 |

15 |

2.2 |

36 |

|

|

|

|

| 10 |

18 |

2.2 |

34 |

|

|

|

|

| HTB32 -160 |

Standard |

7.5 |

35 |

4.0 |

35 |

3.75 |

8.75 |

0.75 |

30 |

K1 |

4.5 |

145 |

| 12.5 |

32 |

6.3 |

8.0 |

| 15.0 |

30 |

7.5 |

7.0 |

| A |

10 |

25 |

4.0 |

35 |

|

|

|

|

| 15 |

23.5 |

4.0 |

36 |

|

|

|

|

| B |

16.5 |

25 |

4.0 |

38 |

|

|

|

|

| 20 |

22 |

4.0 |

39 |

|

|

|

|

| C |

25 |

20 |

5.5 |

38 |

|

|

|

|

| HTB32 -200 |

Standard

|

7.5 |

51.8 |

7.5 |

34 |

3.75 |

12.9 |

1.5 |

28 |

K2 |

4.5 |

270 |

| 12.5 |

50 |

6.2 |

12.5 |

| 15.0 |

48 |

7.5 |

12 |

| A |

5 |

48 |

7.5 |

20 |

|

|

|

|

| B |

12 |

57 |

11 |

25 |

|

|

|

|

| 16 |

54 |

11 |

27 |

|

|

|

|

| C |

17.5 |

41 |

7.5 |

30 |

|

|

|

|

| HTB32 -250 |

Standard |

7.8 |

83.1 |

15 |

27 |

3.9 |

20.8 |

3.0 |

20 |

K2 |

4.5 |

330 |

| 12.5 |

80 |

6.3 |

20 |

| 15 |

79 |

7.5 |

19.8 |

| A |

20 |

60 |

15 |

30 |

|

|

|

|

| 26 |

55.6 |

15 |

33 |

|

|

|

|

| B |

17 |

83 |

18.5 |

29 |

|

|

|

|

| 23 |

80 |

18.5 |

34 |

|

|

|

|

| C |

25 |

70 |

18.5 |

31 |

|

|

|

|

| HTB50 -160 |

Standard |

15 |

35.5 |

5.5 |

52 |

7.5 |

8.8 |

0.75 |

47 |

K1 |

4. |

150 |

| 25 |

32 |

12.5 |

8.0 |

| 30 |

29 |

15.0 |

7.0 |

| A |

20 |

28 |

5.5 |

45 |

|

|

|

|

| 25 |

25 |

50 |

|

|

|

|

| B |

40 |

20 |

52 |

|

|

|

|

| HTB40 -200 |

Standard |

15 |

52 |

15 |

40 |

7.5 |

13.3 |

1.1 |

35 |

K2 |

5.0 |

250 |

| 25 |

50 |

12.5 |

12.5 |

| 30 |

48 |

15 |

12 |

| A |

15 |

41 |

11 |

33.4 |

|

|

|

|

| 20 |

40 |

34 |

|

|

|

|

| 27 |

39 |

45 |

|

|

|

|

| B |

25 |

40 |

40 |

|

|

|

|

| C |

20 |

40 |

31 |

|

|

|

|

| 30 |

35 |

36 |

|

|

|

|

| HTB65 -160 |

Standard |

30 |

35 |

11 |

58 |

15 |

8.75 |

1.5 |

54 |

K1 |

4.5 |

170 |

| 50 |

32 |

25 |

8 |

| 60 |

29 |

30 |

7.13 |

| A |

40 |

28 |

7.5 |

58 |

|

|

|

|

| B |

60 |

25 |

11 |

48 |

|

|

|

|

| C |

52 |

22 |

7.5 |

57 |

|

|

|

|

| 65 |

18 |

11 |

54 |

|

|

|

|

| 75 |

15 |

11 |

50 |

|

|

|

|

| HTB50 -200 |

Standard |

30 |

57 |

22 |

52 |

15 |

14 |

2.2 |

48 |

K2 |

5.2 |

310 |

| 50 |

50 |

25 |

12.5 |

| 60 |

46 |

30 |

11.5 |

| A |

43 |

42.5 |

15 |

48 |

|

|

|

|

| 54 |

39 |

51 |

|

|

|

|

| 60 |

36 |

49 |

|

|

|

|

| B |

42 |

51 |

18.5 |

49.5 |

|

|

|

|

| 58 |

47 |

55 |

|

|

|

|

| 65 |

45 |

55.4 |

|

|

|

|

| C |

70 |

41.5 |

18.5 |

55 |

|

|

|

|

| Parameters/Model |

impeller specifications |

Rated speed 1450 rpm |

Bearing housing |

NPSH margin (m) |

Weight (kg) |

| Flow rate Q (m3/h) |

Discharge head H (m) |

Motor power N

Density of the medium

(kW) (kW) |

Efficiencyη % |

| HTB50 -315 |

Standard |

15 |

32.6 |

11 |

35 |

K3 |

5.2 |

610 |

| 25 |

32 |

| 32 |

30.9 |

| HTB100 -315 |

Standard |

60 |

37 |

22 |

54 |

K3 |

5.5 |

730 |

| 100 |

32 |

| 120 |

30 |

| A |

80 |

30 |

18.5 |

51 |

| B |

110 |

20 |

15 |

52 |

| C |

140 |

34 |

30 |

58 |

| HTB100 -400 |

Standard |

80 |

51 |

37 |

52 |

K4 |

5.5 |

1000 |

| 100 |

50 |

| 120 |

48 |

| A |

120 |

55 |

45 |

50 |

| B |

150 |

48 |

45 |

50 |

| C |

180 |

40 |

45 |

51 |

| HTB125 -315 |

Standard |

120 |

38 |

37 |

65 |

K3 |

5.5 |

750 |

| 200 |

32 |

| 240 |

28 |

| A |

200 |

22 |

30 |

64 |

| B |

220 |

25 |

30 |

65 |

| C |

250 |

24 |

30 |

65 |

| D |

200 |

36 |

37 |

65 |

| HTB125 -400 |

Standard |

150 |

54 |

55 |

62 |

K4 |

5.5 |

1020 |

| 200 |

50 |

| 240 |

45 |

| A |

225 |

47 |

75 |

55 |

| B |

200 |

42 |

55 |

56 |

| C |

200 |

45 |

55 |

57 |

| HTB150 -315 |

Standard |

280 |

35 |

55 |

68 |

K3 |

5.5 |

760 |

| 315 |

32 |

| 360 |

30 |

| A |

320 |

18 |

37 |

62 |

| B |

350 |

24 |

45 |

64 |

| C |

370 |

20 |

45 |

64 |

| HTB150 -380 |

Standard |

310 |

43 |

75 |

68 |

K4 |

5.5 |

1040 |

| 340 |

40 |

| 360 |

37 |

| A |

315 |

38 |

75 |

62 |

| B |

400 |

30 |

62 |

| C |

440 |

28 |

60 |

| HTB150 -400 |

Standard |

320 |

54 |

110 |

66 |

K5 |

5.5 |

1600 |

| 400 |

50 |

| 440 |

48 |

| A |

405 |

37 |

75 |

62 |

| B |

370 |

40 |

90 |

61.5 |

| C |

400 |

45 |

110 |

60 |

| HTB200 -400 |

Standard |

400 |

45 |

132 |

68 |

K5 |

5.5 |

1620 |

| 500 |

40 |

| 600 |

36 |

| A |

480 |

48 |

60 |

| B |

700 |

28 |

60 |

| C |

520 |

42 |

61 |

| HTB250 400 |

Standard |

860 |

33 |

160 |

72 |

K5 |

6.0 |

2200 |

| 1000 |

32 |

| 1180 |

31 |

| A |

1440 |

30 |

200 |

63 |

| B |

1200 |

25 |

160 |

62 |

| C |

960 |

22 |

110 |

60 |

| 750 |

26 |

110 |

60 |

| D |

960 |

36 |

200 |

63 |

| HTB250 -580 |

Standard |

850 |

51 |

250 |

70 |

K7 |

6.0 |

2240 |

| 1000 |

50 |

| 1100 |

48.8 |

| A |

600 |

45 |

160 |

60 |

| B |

750 |

50 |

200 |

60 |

| C |

1200 |

45 |

250 |

68 |

| D |

1440 |

40 |

250 |

68 |

| HTB-Q250 -580 |

A |

600 |

55 |

200 |

60 |

| B |

800 |

50 |

200 |

69 |

| HTB250 -600 |

Standard |

1300 |

59.6 |

355 |

67.5 |

K7 |

8.0 |

2500 |

| 1400 |

58 |

355 |

69 |

| 1500 |

55 |

355 |

70 |

| 1600 |

53 |

400 |

70 |

| A |

600 |

55 |

250 |

56 |

| B |

800 |

55 |

250 |

57 |

| C |

1400 |

45 |

315 |

65 |

| D |

|

|

|

|

| E |

1440 |

60 |

400 |

70 |

| HTB80 -350 |

Standard |

33 |

32.9 |

15 |

40 |

K3 |

5.2 |

620 |

| 50 |

32 |

| 75 |

29.7 |

| Parameters/Model |

impeller specifications |

Rated speed 980 rpm |

Bearing housing |

NPSH (m) |

Weight (kg) |

| Flow rate Q (m3/h) |

Discharge head H (m) |

Motor power N

Density of the medium

(kW) (kW) |

Efficiencyη % |

| HTB400 -700 |

Standard |

2300 |

53 |

450 |

82 |

K9 |

8.0 |

5500 |

| 2500 |

50 |

| 2600 |

45 |

| A |

1600 |

65 |

450 |

74 |

| 2300 |

60.5 |

560 |

80 |

| HTB350 -800 |

Standard |

1865 |

76.8 |

710 |

77 |

K9 |

8.0 |

6500 |

| 2200 |

72 |

| 2650 |

67 |

| HTB350 -450 |

Standard |

1500 |

18 |

132 |

62.5 |

K5 |

6.0 |

2250 |

| HTB450 -750 |

Standard |

2400 |

60.5 |

710 |

77 |

K9 |

8.0 |

6600 |

| 3000 |

55 |

| 3300 |

51.8 |

| Parameters/Model |

impeller specifications |

Rated speed 740 rpm |

Bearing housing |

NPSH (m) |

Weight (kg) |

| Flow rate Q (m3/h) |

Discharge head H (m) |

Motor power N

Density of the medium

(kW) |

Efficiencyη % |

| HTB400 -700 |

Standard |

1890 |

32.8 |

280 |

71 |

K9 |

8.0 |

5500 |

| 2200 |

26.6 |

| 2340 |

23.6 |

| HTB600 -900 |

Standard |

2750 |

63 |

710 |

84 |

|

5.0 |

6750 |

| 3290 |

60 |

| 3600 |

54 |

| HTB600 -700 |

Standard |

4800 |

24 |

450 |

82 |

K9 |

6.0 |

|

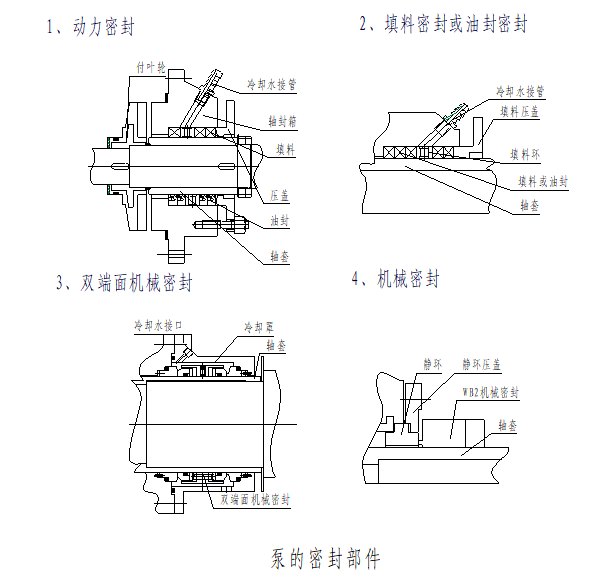

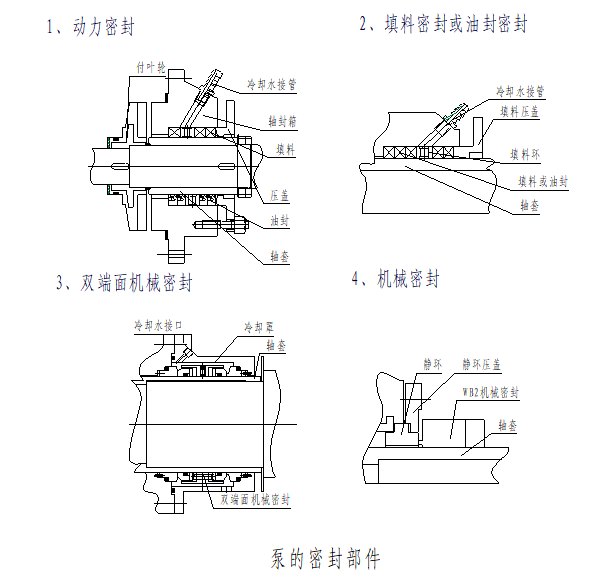

7, Structural description

.png)

Comparison of performance of various sealing components

Comparison of performance of various sealing components

| Sealed form |

Structural characteristics |

Scope of application |

| D-type dynamic seal |

Adopted pay-by-the-hour wheel and parking seal combination, the parking seal is used 3-4 fluororubber oil seals or packing as a seal, simple structure, reliable. |

Mainly suitable for clear liquid or slurry with solid content, and impure sewage, etc., it is a universal seal. |

| T-shaped packing seal |

Expandable polytetrafluoroethylene gasket is adopted, which is resistant to corrosion and wear, simple in structure and reliable in performance. |

Mainly suitable for conveying corrosive media with a large amount of particles and sewage with a large amount of impurities. |

| Y1 type oil seal seal |

Three to four fluororubber oil seals are adopted as sealing elements, which are simple in structure, reliable and low in price. |

Mainly suitable for corrosive media such as clear liquid or slurry with solid content less than 10% and impure wastewater, etc. |

| Y3 type double-end face mechanical seal |

The mechanical seal structure with internal water cooling is adopted, which is expensive and has a longer service life than the seal above. |

Mainly suitable for conveying corrosive media with a large amount of particles, not often used. |

| J type and Y2 mechanical seals |

Adopt the standard structure of WB2 type mechanical seal, the static and dynamic rings can be hard to soft, or hard to hard, and it is not allowed to start the machine empty. |

Mainly suitable for corrosive clear liquid without solid particles, and can also transport media with trace particles when the static and dynamic rings are hard to hard. |

8, Pump external installation dimensions

Installation external dimensions table

| Model |

Power (kW) |

Motor with |

Installation dimensions |

| L |

a |

L1 |

L2 |

L3 |

L4 |

L5 |

B1 |

h1 |

h2 |

DN1 |

D01 |

D1 |

n1-φd1 |

DN2 |

D02 |

D2 |

n2-φd2 |

n-Mdxl |

A |

L0 |

B |

| HTB150-400 |

110 |

Y315S-4 |

2230 |

200 |

140 |

1500 |

300 |

2080 |

750 |

674 |

635 |

450 |

200 |

350 |

390 |

12-M20 |

150 |

295 |

335 |

8-M20 |

6-M24x400 |

100 |

2220 |

880 |

| HTB200-400 |

132 |

Y315M-4 |

2300 |

200 |

140 |

1500 |

300 |

2080 |

750 |

674 |

635 |

450 |

250 |

350 |

390 |

12-M20 |

200 |

295 |

335 |

8-M20 |

6-M24x400 |

100 |

2220 |

880 |

| HTB250-400 |

160 |

Y315L1-4 |

2555 |

350 |

136 |

1500 |

300 |

2100 |

750 |

674 |

710 |

580 |

300 |

460 |

500 |

12-M20 |

250 |

400 |

440 |

12-M20 |

6-M24x400 |

100 |

2240 |

.png)

About usCentury-old enterprise, global brand

About usCentury-old enterprise, global brand ProductsNational key high-tech enterprise with micro-porous ceramics and structural ceramics as the core

ProductsNational key high-tech enterprise with micro-porous ceramics and structural ceramics as the core Research · InnovationNational key high-tech enterprise, national-level non-metallic materials industry base, Jiangsu Province non-metallic materials engineering technology research center, member of the National Separation Machinery Standardization Technical Committee.

Research · InnovationNational key high-tech enterprise, national-level non-metallic materials industry base, Jiangsu Province non-metallic materials engineering technology research center, member of the National Separation Machinery Standardization Technical Committee. ServiceAdhere to the spirit of craftsmanship and strive to create a century of performance.

ServiceAdhere to the spirit of craftsmanship and strive to create a century of performance. Contact usOur company, in line with its policy of "Healthy Sustainable Development", is willing to cooperate with a wide range of peers both domestically and internationally in terms of technology, economy, and trade, to make a due contribution to environmental protection and energy conservation.

Contact usOur company, in line with its policy of "Healthy Sustainable Development", is willing to cooperate with a wide range of peers both domestically and internationally in terms of technology, economy, and trade, to make a due contribution to environmental protection and energy conservation.

(kW)

(kW).png)

Comparison of performance of various sealing components

Comparison of performance of various sealing components.png)