Properties

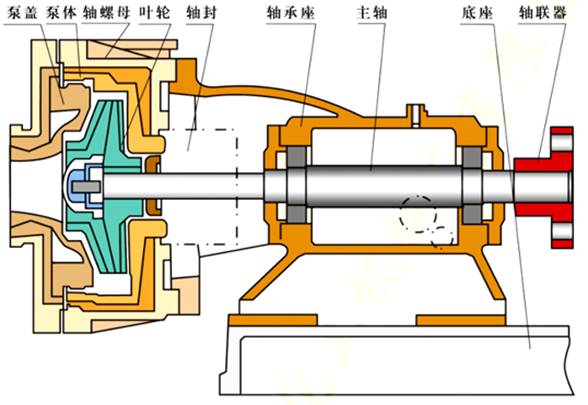

Body and cover are made of Anticorrosive , wear-resisting acid-proof ceramic , with casting iron as external body. Impeller is closed impeller, with ceramic and plastic as materials. Flow 5~100m3/h, Lift ≤ 50m , Temperature< 100 ℃. Seal is Mechanical seal or Dynamic seal .

Application

Suitable for non-quick-cured media. except HF and hot caustic soda or media with suspension particles. Widely used in non-ferrous metal smelting, non-mineral processing, environmental engineering, sulfuric acid, phosphate, chlorinate alkali, citric acid, water treatment, chemical fiber, electroplating, steel industry etc

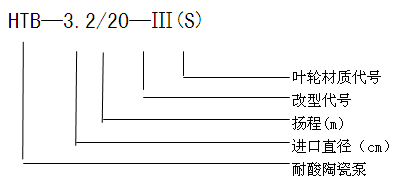

Model

Codes of impeller materials

Materials | ceramic | UHMWPE | Modified rubber | Fluoro-plastic alloy | PVDF | Chlorinated polyether | Stainless Steel | ||

Anticorrosive & wear-resisting | Heat-resisting & wear-resisting | Anticorrosive | |||||||

Code | without note | S | S1 | S3 | S2 | S4 | S5 | S6 | G |

Structure type

Parameter details

Parameters \ Model | Specification of impeller | Rated Rev. 2900 r/Min. | Rated Rev. 1450 r/Min. | NPSH | Weight | ||||||

Flow Q (m3/h) | Lift H | Power of motor N | Efficiency η % | Flow Q | Lift H | Power of motor N | Efficiency η % | ||||

HTB3.2/20 | Standard | 8 | 22 | 2.2 | 45 | 4 | 5.5 | 1.1 | 40 | 4 | 60 |

12.5 | 20 | 6.25 | 5 | ||||||||

16 | 15 | 8 | 3 | ||||||||

HTB5.0/32 | Standard | 20 | 33 | 5.5 | 51.5 | 10 | 8.2 | 1.5 | 45 | 5 | 110 |

25 | 32 | 12 | 8 | ||||||||

30 | 30 | 15 | 7.5 | ||||||||

HTB10.0/32-168 | Standard | 50 | 34 | 15 | 45 | 25 | 8.3 | 3 | 40 | 6 | 230 |

60 | 32 | 30 | 8 | ||||||||

70 | 30 | 35 | 7 | ||||||||

HTB10.0/50 | Standard | 70 | 52 | 30 | 61.5 | 35 | 13 | 5.5 | 56 | 5.5 | 230 |

80 | 50 | 40 | 12.5 | ||||||||

90 | 48 | 45 | 12 | ||||||||

HTB10.0/40 | Standard | 90 | 43 | 30 | 60 | 45 | 10.5 | 5.5 | 55 | 5.7 | 250 |

100 | 40 | 50 | 10 | ||||||||

110 | 38 | 55 | 9 | ||||||||

HTB10.0/15-M | Standard | 35 | 15.5 | 5.5 | 57 | 3 | 230 | ||||

40 | 15 | ||||||||||

45 | 14 | ||||||||||

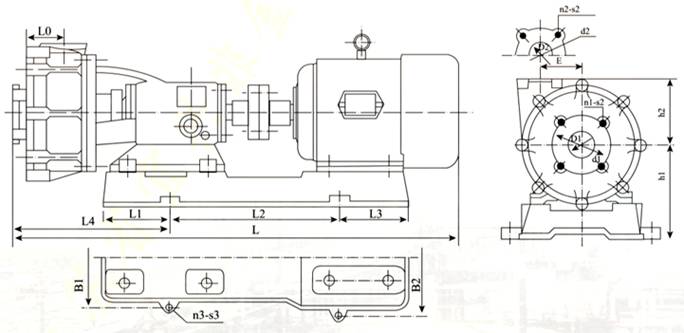

Pump shape and Installation size

Installation size

Model | D1 | D2 | d1 | d2 | B1 | B2 | n1-s2 | n2-s2 | n3-s3 | E | h1 | h2 | L1 | L2 | L3 | L4 | L | Weight(except motor) kg |

HTB3.2/20-Ⅲ-U | 32 | 25 | 100 | 85 | 260 | 32 | 4-M10 | 4-M10 | 4-φ18 | 81 | 160 | 110 | 97 | 336 | 97 | 308 | 804 | 60 |

HTB5.0/32-Ⅲ-U | 50 | 40 | 125 | 110 | 320 | 50 | 4-M12 | 4-M12 | 4-φ20 | 98 | 212 | 150 | 160 | 400 | 160 | 320 | 992 | 110 |

HTB10.0/50-Ⅲ-U | 100 | 80 | 210 | 185 | 385 | 100 | 4-φ18 | 4-φ18 | 4-φ20 | 140 | 335 | 200 | 188 | 665 | 207 | 380 | 1398 | 230 |

HTB10.0/15-M1-Ⅲ-U | 100 | 80 | 210 | 185 | 385 | 100 | 4-φ18 | 4-φ18 | 4-φ20 | 140 | 335 | 200 | 180 | 504 | 180 | 380 | 1106 | 230 |

HTB10.0/32-168-Ⅲ-U | 100 | 80 | 210 | 185 | 385 | 100 | 4-φ18 | 4-φ18 | 4-φ20 | 140 | 335 | 200 | 180 | 534 | 206 | 380 | 1236 | 230 |

HTB10.0/40-Ⅲ-U | 100 | 80 | 210 | 185 | 385 | 100 | 8-φ18 | 4-φ18 | 4-φ20 | 136 | 335 | 200 | 188 | 665 | 207 | 405 | 1423 | 250 |