Properties

Flow : 5~240m3/h Lift : 10~60m, Back blade of impeller pressure-reduced combined with fluoro-plastic Oil seal ring or auxiliary impeller Centrifugal seal . Suitable for Corrosive, abrasive media. except HF and hot caustic soda, or media with suspension particles. Operating temperature <100℃( depends on Operating temperature of engineering plastic, Materialsand media), Sharp Temperature difference<50℃.

Application

Can be widely used in conveying the corrosive medium containing solid particles.in mining, metallurgy, chemical industry, petroleum, chemicals, dye, sewage treatment, and other industry

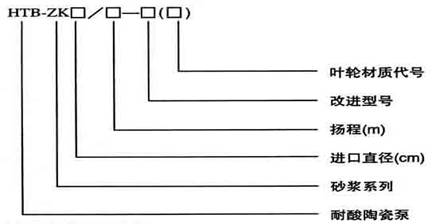

Model

Codes of impeller materials

Materials | ceramic | UHMWPE | Modified rubber | Fluoro-plastic alloy | PVDF | Chlorinated polyether | Stainless Steel | ||

Anticorrosive & wear-resisting | Heat-resisting & wear-resisting | Anticorrosive | |||||||

Code | without note | S | S1 | S3 | S2 | S4 | S5 | S6 | G |

Parameters \ Model | Specification of impeller | Rated Rev. 2900 r/Min. | Rated Rev. 1450 r/Min. | NPSH | Weight | ||||||

Flow Q (m3/h) | Lift H | Power of motor N Specific gravity of media | Efficiency η % | Flow Q | Lift | Power of motor N Specific gravity of media | Efficiency η % | ||||

HTB- | Standard | 5 | 24 | 2.2 | 33 | 1.5 | 4.0 | 60 | |||

10 | 20 | 37 | 5 | 5 | |||||||

15 | 16 | 35 | |||||||||

A | 5 | 12 | 1.5 | 26 | |||||||

B | 5 | 15 | 1.5 | 26 | |||||||

C | 8 | 10 | 1.5 | 27 | |||||||

HTB- | Standard | 10 | 33 | 5.5 | 40 | 5 | 8.2 | 1.5 | 4.0 | 110 | |

20 | 30 | 43 | 10 | 7.5 | |||||||

30 | 27 | 41 | 15 | 6.7 | |||||||

A | 30 | 22 | 5.5 | 36 | |||||||

B | 20 | 20 | 4.0 | 35 | |||||||

25 | 18 | 5.5 | 36 | ||||||||

HTB- | Standard | 25 | 51.5 | 15 | 36 | 12.5 | 12.8 | 3 | 5.0 | 220 | |

30 | 50 | 41 | 15 | 12.5 | |||||||

40 | 45 | 39 | 20 | 11.2 | |||||||

A | 15 | 50 | 11 | 35 | |||||||

B | 20 | 45 | 11 | 35 | |||||||

C | 25 | 40 | 11 | 35 | |||||||

HTB- | Standard | 30 | 32.8 | 11 | 43 | 15 | 8.2 | 2.2 | 5.0 | 188 | |

40 | 30 | 48 | 20 | 7.5 | |||||||

50 | 29 | 46 | 25 | 7.2 | |||||||

A | 30 | 27 | 7.5 | 42 | |||||||

40 | 25 | 7.5 | 44 | ||||||||

50 | 23 | 11 | 45 | ||||||||

HTB- | Standard | 50 | 37.5 | 18.5 | 50 | 25 | 9.4 | 3 | 5.0 | 220 | |

60 | 35 | 52 | 30 | 8.8 | |||||||

70 | 31 | 49 | 35 | 7.8 | |||||||

A | 50 | 32 | 15 | 50 | |||||||

60 | 29 | ||||||||||

HTB- | Standard | 150 | 28 | 37 | 58 | 6.0 | 410 | ||||

220 | 25 | 65 | |||||||||

240 | 22 | 60 | |||||||||

A | 150 | 35 | 45 | 49 | |||||||

200 | 32 | 52 | |||||||||

240 | 28 | 50 | |||||||||

HTB- | Standard | 120 | 43 | 37 | 51 | 6.0 | 520 | ||||

150 | 40 | 45 | 58 | ||||||||

200 | 37 | 45 | 56 | ||||||||

A | 100 | 45 | 37 | 50 | |||||||

B | 130 | 35 | 30 | 52 | |||||||

C | 160 | 45 | 45 | 56 | |||||||

HTB- | Standard | 100 | 27 | 30 | 53 | 6.0 | 360 | ||||

120 | 25 | 57 | |||||||||

140 | 24 | 58 | |||||||||

A | 85 | 22 | 15 | 46 | |||||||

100 | 20 | 50 | |||||||||

120 | 18 | 52 | |||||||||

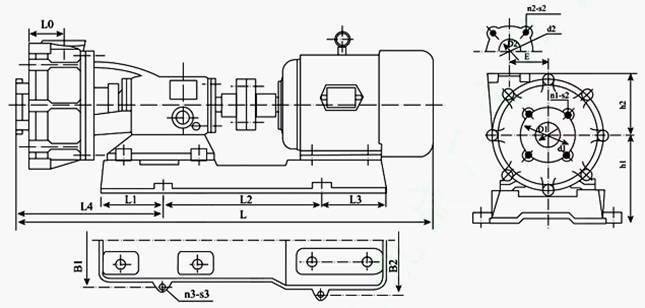

Pump shape and Installation size